With Failure Mode and Effect Analysis

| FMEA in six steps |

|---|

| Definition of Scope |

|

| Structure Analysis |

|

| Function Analysis |

|

| Failure Analysis |

|

| Risk Analysis |

|

| Optimization |

| böDIDesign | Industrial- & Mediadesign |

| AIM-IR Module GmbH | Development and production of IR detectors and Stirling coolers |

| BBQ Education GmbH | SIA student engineer academy ( start 2000+) and other educational Projects |

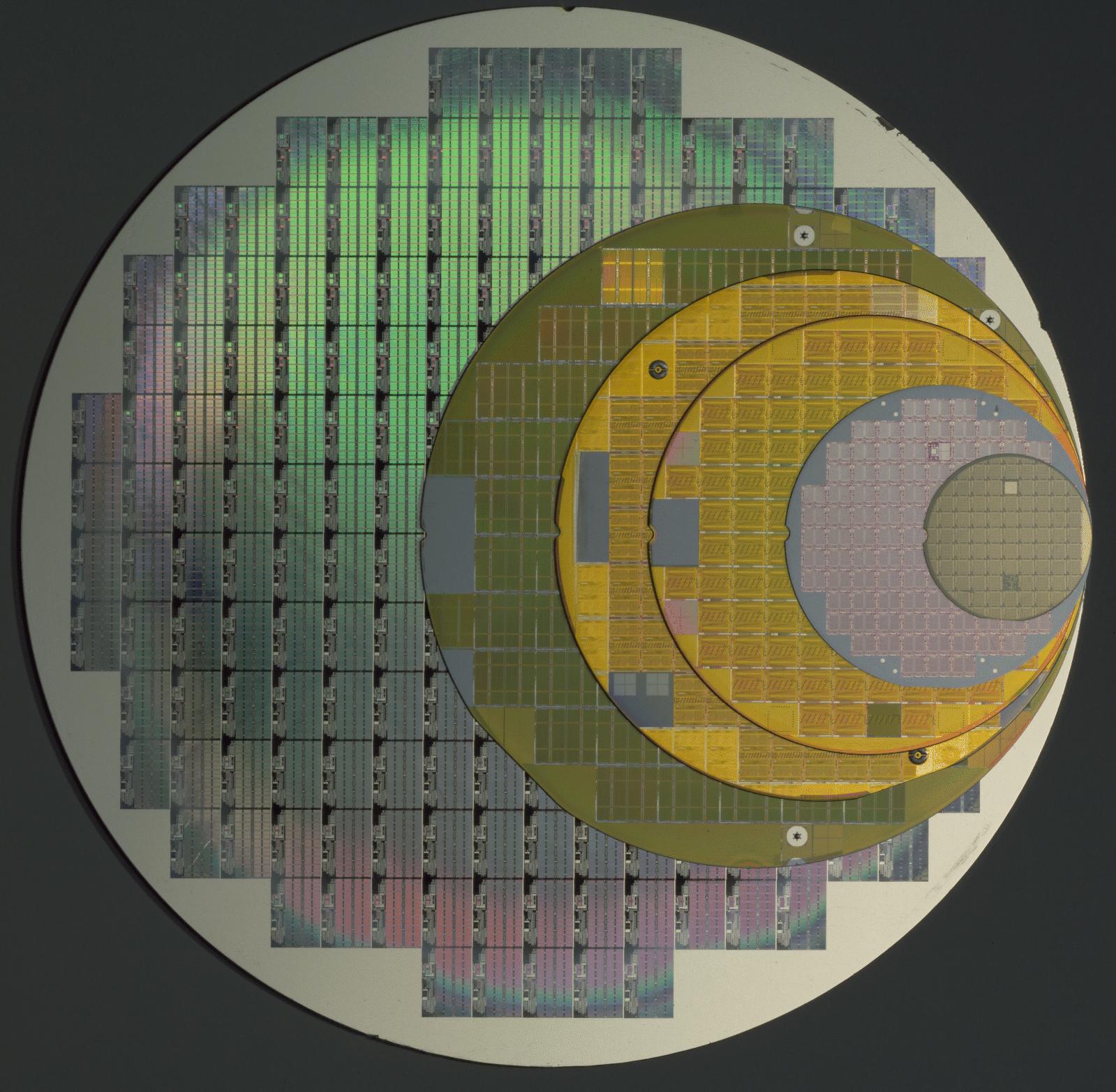

| Dialog Semiconductor GmbH | Mixed Signal Integrated Circuit Development |

| PLATO AG | Solutions for optimizations of business processes in the fields of Engineering, Compliance and Quality Management |

| TC CW/BB | Technology Network Calw-Böblingen – Consulting service for technology companies |